jabowery,

"They are notoriously difficult to handle ..." Not really, I worked with them

extensively in the 40's and 50's. See:

http://www.dtic.mil/dtic/tr/fulltext/u2/315660.pdf See page 8. Still work with "Sensitive?" materials. Presently have Fe pipe nipple +

2 caps. Loading 5% "Mix" with 95% Zeolite. One cap tight, one cracked a bit.

This is placed into larger PVC pipe section with one end glue tight + implanted gas

valve for alternate evacuating / charging with propane and the other end

capped with silicone grease to make non permanent seal. Must purge out O.

The propane is cheap, easy to work with and disintegrates into soot and active H.

The Mix follows these proportions:

NiCl2{H2O}6 + 7Mg => Ni + MgCl2 + 6MgO + 6H2

237.6 170.1 58.7 12

with excess Mg (Fireworks) powder, thorium lamp mantle and trial tid bits of

catalyst. The PVC cap is eased off with a tiny + propane pressure and the

Fe caps tightened with heavy monkeys. Dug 10' hole out back & installed 12'

4" PVC pipe capped on bottom. Wrapped nipple with used nichrome heater wire,

insulation and thermocouple. Proceedure is: lower unit, stand away, heater on

and heater off at 450 C. Goal: Excess heat or new commercial explosive via

fusion. This all started when I dated Dr. Robert W. Wood's granddaughter one

40/s summer and he showed me his barn. She showed me the moon through

diffraction grating that night.

http://www.google.com/url?q=http://www.nasonline.org/publications/biographical-memoirs/memoir-pdfs/wood-robert-1.pdf&sa=U&ei=8cuHULyMCYeY9QTFrYCgAg&ved=0CBcQFjAB&usg=AFQjCNEYCSljYjxZEJcrdaPMUQqa6QUoCQTry tiny tad of Borax.

Chan

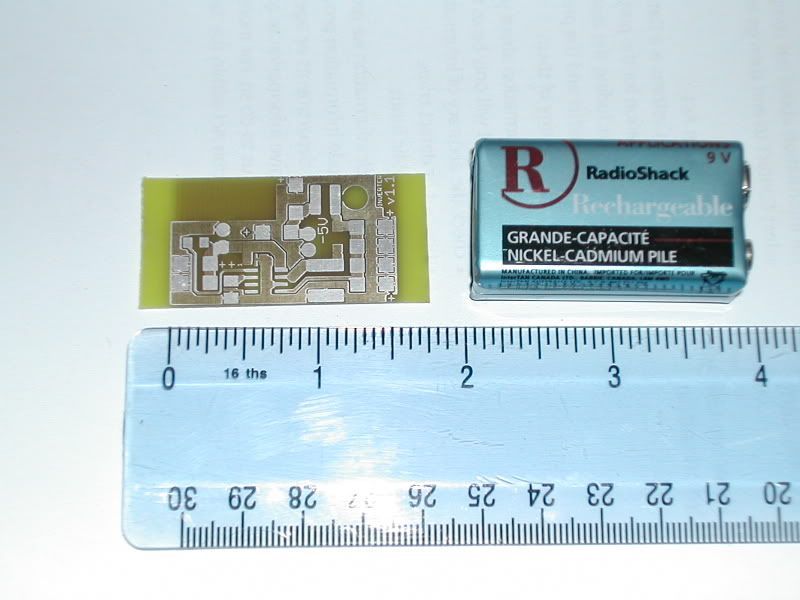

PS: Thank you simonderricutt for

http://fullnet.com/~tomg/gooteepc.htmWhat an exciting new world. And thank you Russ for assembling a great group

of diverse lads and lassies who are allowed to contribute somewhat off topic

comments. God bless you all.