Glad that there are still a few of us working on this.

I've all but given up, not even sure what step to take next. I just put all my lab stuff away the other day as we had a guest staying in that room. I'm not sure if I even want to take it back out: (

I feel I have tried everything and have yet to see any results. Its been over 10 years now, I just wish I knew where my mistake was...

Perhaps its time to share more info and brainstorm as a team again?

========================================

========================================

:) :) :) :) :) :) :) :) :) :) :) :) :) :) :) :) :) :) :) :) :) :) :) :) :) :) :

HAPPY NEW YEAR 2018 -

NEW RESOLUTION HAVE THIS FULL COMPLETE AND RE DOCUMENTED PROMOTED AND VIDEOS BEFORE 2020

We are Working we can lower the thresh hold and raise tun ability stability this way

Have a Great Year and Do Great Things

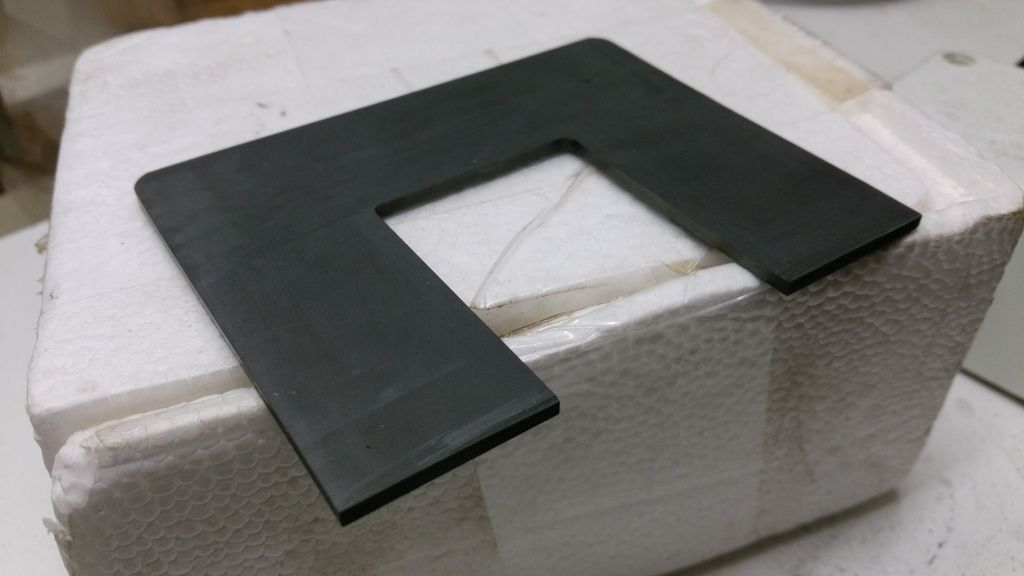

Add the Dielectric barrier to it now

https://youtu.be/IDth0hPv-1go Focusing we must publish which has be dielectric, properties and will now dissolve and enter water from h2 exposure etc or degrade, and which is malleable for the different cell types tube cell wet , tube cell dry, wet cell plate,(browns) (meyers) and plate dry we can compare and fine tune the data here and post,

so far we have

mica paper/ plates or mica dielectric ? k volts per mm

Glass tube or plate ? mm ( from ozone machine type manufacture) , dielectric ? k volts per mm

The Ozone Glass Factory states ( Electric insulation: 10000 times of usual glass) But does not state k per mm

=======================

Let study look at dielectric k volts per mm and stability if in water or h2 please pose what you find on each above reply we can work out bet thinnest result

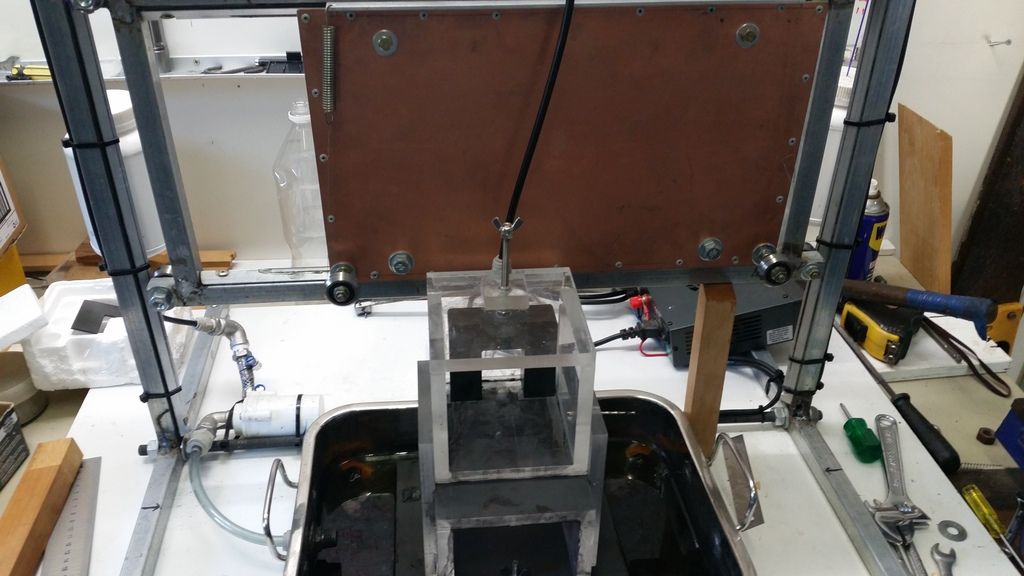

Stan Meyer Tall Wet Cell Tubes ( longer the tubes more gas yields) 9 Cell

The Critical InFo you Want

Outer tubes 1 inch diameter,

inner tubes 3/4 inch diameter

Thickness 1/16 inch

316 L Stainless Steel. or higher.

16 to 18 inches long 418 mm to 458 mm

Gap 1mm to 2mm

9 Tube sets ( 18 Tubes inner and outer)

Sta Meyer 11 Cell Wet Cell Tubes the anode and cathode SS tube and rod. I will begin there. 1/2" rod and 3/4" tubing. The rod will be cut down to 4" in length with the slots milled and drilled on the ends. The tube is .035" wall which will be machined down to .030" wall and 2.75" in length.

Plates wet cell are 12.5 cm diameter as a start size

so the glass tubes or plates of mica etc starting point Tubes 20 mm diameter inner 9 Tube Wet Cell Meyers) & 13 mm diameter inner ( 11 Cell design wet cell meyers)

2 Disc or square 12.5 cm and 8 cm diameter ( plate wet cell Brownes and or meyers

Please not these sizes are guesstimates we want the glass or coating to be on touching sealed to cathode if that is center tube rod so fitment is tighter the better , so some advise eon precise sizes need fine tuning here and positing

Coffee Time

O:-)Ref video

Tony Quinn and Valentin Petkov /valyonpz/

Dan Secure Supplies

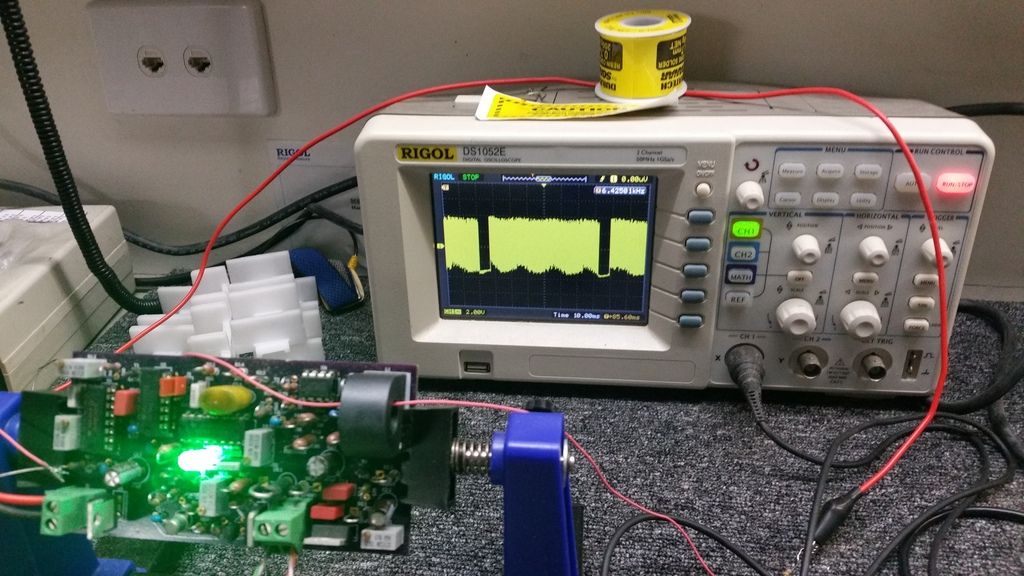

We have to be careful not to use any pre-amplifiers since they will add more slew to the signal.

We have to be careful not to use any pre-amplifiers since they will add more slew to the signal.