Maybe I don't get it but does anyone see a problem with this basic design that 1/2 the power is wasted?

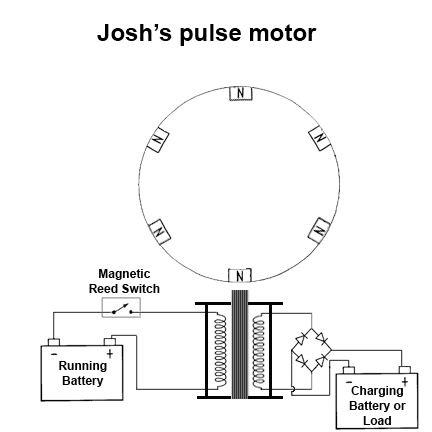

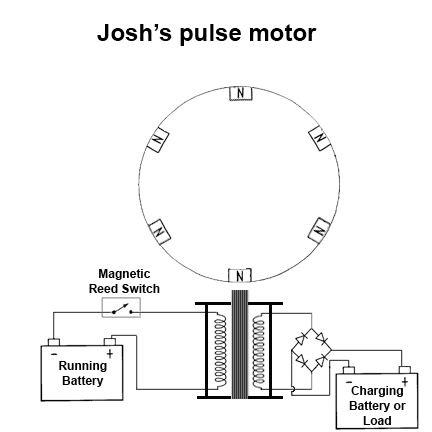

(random picture found online as a rough example, the same can be said about a Bedini motor or some other motors )

I must be wrong on something since many would have seen it and done something, so when they don't then that means I don't get it... right?

You have the electromagnet which can push "North" (for example) the magnets in the center wheel from the side that is facing it. But shouldn't the electromagnet side that is facing away "South" (that can pull) from the device be used too?

For example wouldn't it be better if the pulling side "South" was used and attracting another wheel? Or have the electromagnet in a U Tube that goes back to the wheel? Or Maybe have the electromagnet be in a C shape which both the north and south side hit both sides of the same magnet on the wheel?

I see plenty of commercial motors just use one side of the electromagnet while the other side is not use to be wasted. Or does using both sides of the electromagnet weaken one side?

You notice how when you turn on a light it radiates all over and you have a reflector to focus the light at a point to make it stronger and more efficient in what you want to see. So wouldn't that principle in a way be kind of used in focusing or using all the electromagnet's magnetism all over to not have loss? Even a fire in zero gravity radiates and one can not cook as efficient if the fire is not concentrate if it radiates.

I can even go as far to say maybe the magnetism around the electromagnet is wasted which being inside a tube make the outside tube magnetic as well? To have a tube, the magnetized wire, then a tube again.

Thanks

(random picture found online as a rough example, the same can be said about a Bedini motor or some other motors )

I must be wrong on something since many would have seen it and done something, so when they don't then that means I don't get it... right?

You have the electromagnet which can push "North" (for example) the magnets in the center wheel from the side that is facing it. But shouldn't the electromagnet side that is facing away "South" (that can pull) from the device be used too?

For example wouldn't it be better if the pulling side "South" was used and attracting another wheel? Or have the electromagnet in a U Tube that goes back to the wheel? Or Maybe have the electromagnet be in a C shape which both the north and south side hit both sides of the same magnet on the wheel?

I see plenty of commercial motors just use one side of the electromagnet while the other side is not use to be wasted. Or does using both sides of the electromagnet weaken one side?

You notice how when you turn on a light it radiates all over and you have a reflector to focus the light at a point to make it stronger and more efficient in what you want to see. So wouldn't that principle in a way be kind of used in focusing or using all the electromagnet's magnetism all over to not have loss? Even a fire in zero gravity radiates and one can not cook as efficient if the fire is not concentrate if it radiates.

I can even go as far to say maybe the magnetism around the electromagnet is wasted which being inside a tube make the outside tube magnetic as well? To have a tube, the magnetized wire, then a tube again.

Thanks